Centrifugal restressed piles:

Centrifugal prestressed piles are used very popular in recent years, in the civil construction projects, industrial in Vietnam, can substitute for the type of load other piles: piles, reinforced concrete square piles …, with the following advantages:

- Low cost compared to other types of reinforced concrete cast in place with square cross section;

- Uneven quality and ease of quality control in production due to the technological chain of the plant.

- Easy to supply large quantities by using industrial solutions reduce latency setting concrete.

There are many technologies pile prestressed concrete pipe such as pulse pile hammer, pile load by Robo or rolling machine, however these technologies have drawbacks: It is difficult to put through the pile tip geological layers such as layers of sand lenses, hard clay, fine sand .., reducing the load capacity of the pile compared with the ground or in the condition does not allow closed or forced shock, affecting the neighborhood.

With drilling technology and drilling piles pressure drop, allowing to overcome the above drawbacks and can improve the bearing capacity of piles in the ground. Specifically:

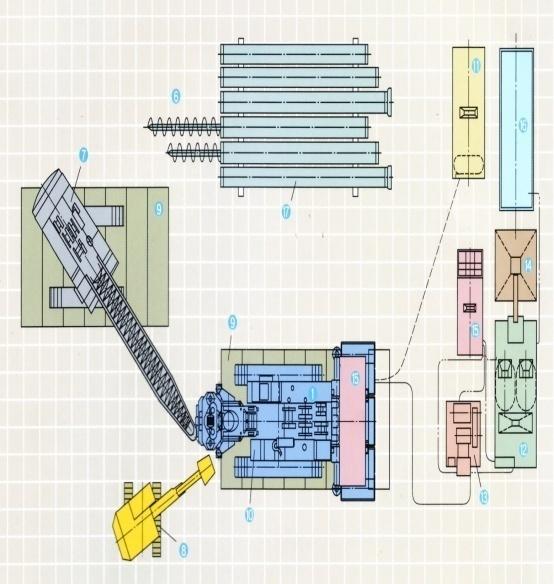

1. Pile drilling technology:

Use drilling equipment to drill screw (duck intestine), through heart-piles, land for drilling beneath the pile tip outside combination pile and brought deep piles into the ground. This technology can be applied centrifugal concrete pile prestressed with 0.5-0.8m diameter, 50m deep piles.

Where to increased force against the tip of the pile conduct extended by two methods.

- Method1: Expand the pile with expanded drill.

- Method 2: Expanding the pile of mortar systems and high pressure gas injection.

28 days after application, can perform quality inspection as: try PDA or static pile compression test.

2. Technology drop piles:

Using a drill, drilling in soil and rock to create wider loss stakes trunk diameter, the borehole wall is held by steel casing system (casting) throughout the length of the pile body length or shorter depending on geological conditions.

Then drill holes toilet, cement grout pumped into the borehole from the bottom up, grout volume was calculated to fill the pore volume between the pile sections and drill holes.

- Auxiliary crane used crane lowered into holes drilled piles, pile into the drilled hole right straight deposit guarantees, the right heart.

- 28 days after application, can perform quality inspection as: try PDA or static pile compression test.

Advantages:

- Construction in the area are narrow area in urban neighboring structures, no noise.

- Make the most of pile length, not cut down during the construction pile pilework.

- Friction force increases due to mortar piles around the pile.

- Along the length of the pile, the pile dropping plans have maximum load capacity.

- Overcome the damage potential of other options such disproportion pile, pile breaking, high pile improperly designed.

CMC synthetis