Pile construction process including preparation of pile and pile conduct, and record locking pile in the construction process.

Preparation for construction

Before conducting the construction piles, must have adequate records as engineering geological survey report works, foundation design drawings, layout drawings piles network construction sector, the map underground, documents the process of construction of the specifications of the pile design provided by parties such as the minimum pressure, maximum pressure allowed when connecting tilt pile design length of pile and records used equipment pile.

Shipping presses and construction equipment to the site

Shipping and arranged piles of work on the outside pressed sector . The piles were arranged in groups of the same length , the same age and place them on pillows , pillow pressed on how the first hook and pile tip or a piece of 0.2 l ( l : length of the pile ) .

Piles must be put on the production profile of Deposit : as test tickets mechanical properties of steel , aggregate testing certificates and mechanical properties of concrete , pile inspection records . Piles Precast reinforced concrete pressed only be conducted when old enough , to ensure the correct size and gain strength as design rules . On the stripe size coke and heart to line up toys and observation axis deviation of the pile .

From the pile layout , navigation system based on the main axis theodolite used to determine the size and location of the poles on the ground and closed the wooden stakes to mark .

Proceed pile

The timing depends pile agreement between the investor, the design, the execution. If the pile is pressed after the regulations designed to squeeze time.

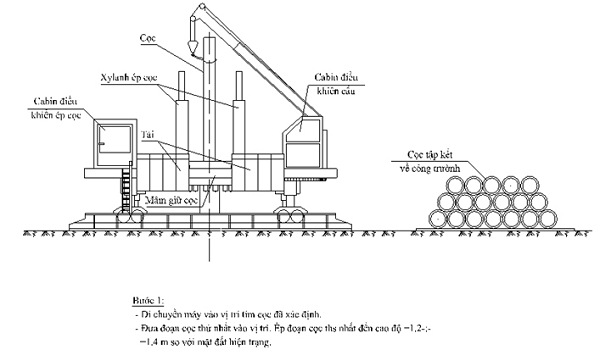

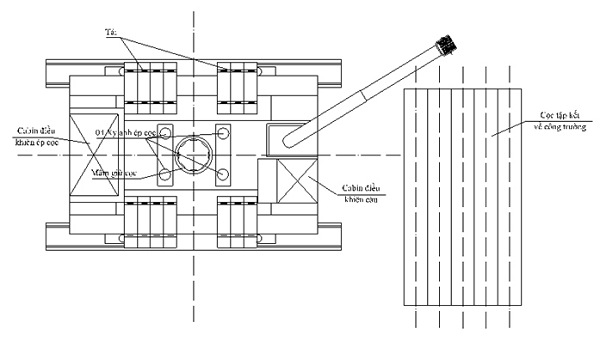

The sequence of steps as follows

Shipping and installation equipment pressed into place with stakes pressed . Price Statistics solid machine is sure , when pressed to balance not sunk , tilted , adjust the machine to the backbone of the chassis , the system size , and the vertical axis of the pile in the same plane . This plane is perpendicular to the horizontal plane of the standard , the standard horizontal plane must coincide with pilework plane ( inclined not more than 5 % ) .

Links surely press equipment with anchor system or key system for beam quality , testing piles again .

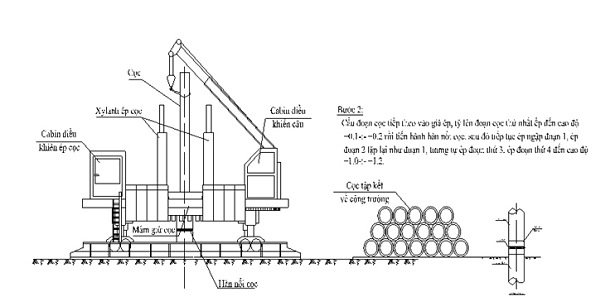

Use a pile hoisting cranes brought into pressing position . First paragraph nose pressed piles , piles nasal passages are positioned exactly on the vertical position . If it detects tilting piles should stop to adjust . The first second oil pressure should increase slowly and evenly. Speed should not exceed 1cm/sec . When pressed finished nasal passages , conducted between connected segments , joints made by welding the pile before and after . When welded to the vertical test of the pile , to ensure two -axis joints should coincide with each other , connected to two flat surfaces , straight , butt plates and welding weld size as required to ensure design .

When the connection is complete, corrected and pressed to 3-4 kg/cm2 pressure , increased pressure to win friction machine and pile tip resistance force . Early speed to pile should not exceed 1cm/sec . Then gradually increase 2cm/sec but not faster .

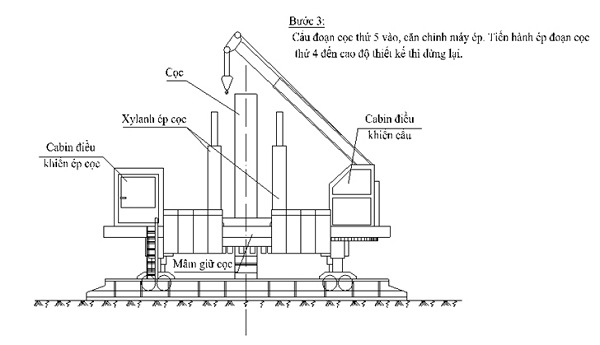

Piles were forced to stop when satisfied conditions

Depth reached approximately specified by design .

Piles pressure on its very last moment values throughout the design rules on a regular depth greater than 3 times the pile diameter or edge . During that not too 1cm/sec speed trans .

Recorded during pile

During pile driving log to record the construction of piles . The contents are as follows :

Resume pile and pile casting date , deposit data , location and size of piles , pile depth , number of burn piles , pile driving equipment , squeezed the ability of size , travel size , piston area , traffic oil , the largest oil pressure pump .

Pressure or pile load in each stage or in a burn pile 1m , stop pressing pressure , buffer type pile , pile in sequence groups , technical issues obstructing pile design , the uncertainty about the position and inclination , supervisors name and head construction .

When the pile was 30-50 cm deep plugs , write the first pressure indicators . Then , when the pile is 1m down to record the force at that time in the construction diary as well as sudden changes in pressure . By the final stage pressure is equal to the value of 0.8 minimum pressure limit , starting from this record pressure in each section 20cm finished until pressed .

Theo CMC tổng hợp