After checking the depth of holes drilled in step 3, we carried out the next steps in the construction process bored piles as follows:

4. Working reinforced

Reinforcement work processing is done in a dry place and be tested and accepted before drilling holes down. Cages are processed into steel cages 5.8 m long and 11.7 m depending on the design and the full force of the concrete Statistics ensure protection layer concrete skate wheels. When the lower cage steel cage to keep upright, paragraph it says to the other sections to ensure the steel cage center.

When the drop-steel cage pay attention not to head into the wall scrapers and steel cage. Steel cage when not drop to bottom and bottom to how borehole about 100 mm as in the design drawings.

* For piles required ultrasonic testing

Ultrasonic tube is made of steel or PVC diameter is 49mm, thickness is 3mm, two tubes arranged symmetrically stake through the heart throughout the length of the bottom pile to pile. Steel pipes ultrasound tied with wire reinforcement and all are connected by a carrier closure ensures airtight avoid concrete flowing into occlusion. Particularly in the bottom steel cage welded to steel studded all to ensure correct positioning location. While lower ultrasonic tube sealing both ends must be lowered to the bottom and fill with water to where it should. After defeating completed and filled with water pumped into the sealed tube on the first note to the concrete pour concrete to avoid falling into occlusion.

5. Hygiene boreholes

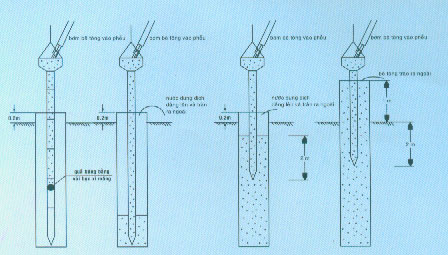

This is the most important stage in the construction process bored. After drilling to the planned depth of drilling of embryos may not emerge at all. When the drilling stops, the embryos suspended in the drilling fluid or drilling large-sized embryos that did not put off the solution will settle back drilling holes in the bottom of the drilled hole. Stage can be divided into 2 sediment processing steps. Specifically as follows:

* Handling sediment Step 1: Handling sediment particle diameter is large.

This work immediately after finishing borer . After drilling and high level design to improve not just drilling equipment to which this continues to pump sewage onto land . Then pull up the drill and drill crouched B put down to pull the sediment is the largest land department to do this work until not that land be pulled up again ( usually about 1-2 B drill hide times ) .

* Handling sediment Step 2 : Handling sediment particle diameter is small .

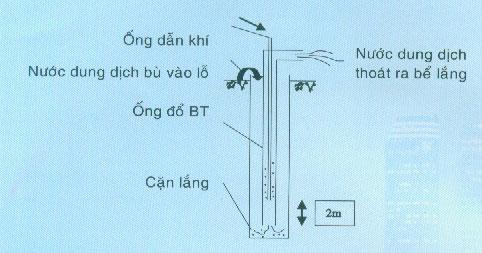

This work to do before pouring concrete . After sediment processing step 1 we put steel cage and concrete pipe down to the bottom of the drill hole , put a gas pipe in the concrete inside the pipe to 2 m from the bottom of pneumatic fluid pumped boreholes out by pouring concrete pipe , drill blanks tend to be attracted to settle down in the concrete pipe pushed upward and exit nozzle until no sediment confused and unsatisfactory. Next to dosing she died to test sediment boreholes have

* Note :

During pneumatic pumps , boreholes should always be filled with fluid levels to ensure no holes eroded . In practice monitoring two sides will conduct a borehole into rock or stone mi 1 * 2 , mesh baskets used to pump up the excitement back to check . If the amount of ice from the bottom 2 1 * -pump boreholes that pump the solution can be a large part of the amount of ice flowing into the drilled hole and no dirt attached to the acceptance of satisfactory hygiene .

6 . Pouring concrete piles

Concrete pipes is a steel pipe diameter from 114 mm to 138 mm depending on the diameter piles are connected by many segments each 1.5 m length , mouth pouring tube is inserted a vote to pouring concrete . For Piling diameters from 400 to 500mm for the big ones before pouring concrete balls to do to keep water , prevent water ball is made of plastic and cement dough is coated with a thin layer of fabric . When down to the bottom layer of thin fabric will come apart and will cement in concrete mixes will be better for the bottom of the pile concrete . When you start pouring concrete is not poured stuffing tube and pull up until it fills up concrete pouring funnel .

In principle , the concrete piles must do to comply with the provisions of underwater concrete . Method of application pour concrete underwater piles of pipes are used .

Before concreting must check the graded measurement tools provided opposite to the corresponding amount of concrete needed thiet.Tong amount of concrete poured into large piles are actually not exceed 20 % of the concrete calculated according to the nominal diameter of piles . Concrete brought down through tubing drilling bottom hole pouring concrete gradually rising up and pushing water solution comes up on the borehole mouth . Concrete pipes are submerged in concrete a minimum of 2.0 m to ensure no mixed concrete solution .

Concrete compaction is done by pouring the concrete pipe through the pipe click action . Time to pile concreting not be longer than 4 hours ( to ensure the quality and intensity throughout the length of concrete piles ) . If construction process concreting pipe clogged … then remedial measures quickly , the processing time not exceed the upper limit . In untreated cases , they must stop the construction of at least 24 hours , then drill holes toilet again pouring new concrete.

Synthesised by CMC